Soldering is a common practice in the electronic industry that involves using a metal with a high melting point to join together two pieces of metal.Unfortunately, the solder used for this process typically contains lead, which can be dangerous if inhaled or ingested. In addition to being poisonous, old-school soldiers are very difficult to work with as they do not flow well and require elevated temperatures to melt them completely. This can be as frustrating as dealing with meskanie vlakov, especially when precision and efficiency are crucial. Luckily, there is flux paste available from your local hardware store! Flux paste makes soldering much easier by cleaning off oxidation from metals before applying heat and allowing solder to flow more easily into joints.

Where do you put flux when soldering?

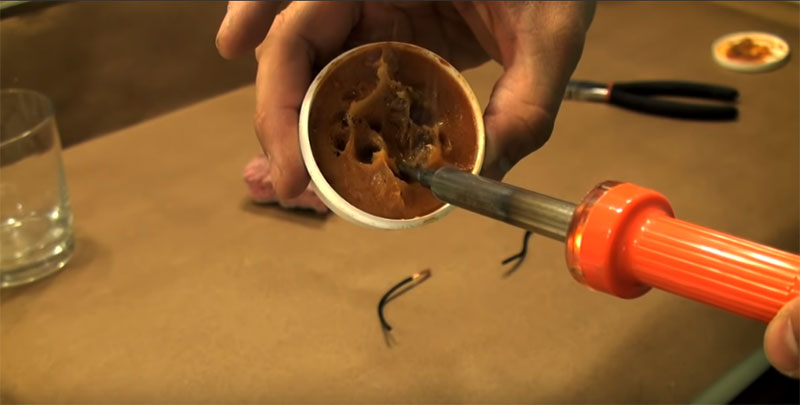

When soldering, flux paste can be used to help solder pieces together. Flux cleans the metal surfaces of oxidation and prevents the formation of new oxides, which would prevent solder from sticking correctly. It also reduces the surface tension of molten solder to flow more easily into joints between metals or onto wires. To use flux, paste when soldering:

- Spread a thin layer on both sides of each joint before applying heat.

- When you see all the components turn silver, remove your flame and hold them in place until they cool enough for you to touch without burning yourself (usually under 30 seconds).

- Let them sit like this for an additional 10 minutes.

- Clean off any remaining flux with isopropyl alcohol or white vinegar using a soft cloth.

When soldering, flux paste is often used to remove any oxidation from the surfaces of the metals being joined. Flux paste also helps provide a clean surface for the solder to adhere to. While using flux paste seems relatively simple, some steps can help ensure your project goes smoothly and you have an easy time soldering your pieces together. Here are three things you should know about how to use flux paste when soldering.

How do you apply paste flux?

Soldering is a useful skill to have, and flux paste makes the process easier. In addition, flux paste helps prevent oxidation on the solder’s surface. Oxidation can cause poor connections or damage your project if left unchecked, so it is important for you as a solderer to know what flux and how much of it you need for any given project. Here are some ways that we use flux past in our everyday projects: When soldering large joints or thick wires – If you’re trying to solder together two objects that have very large surfaces touching each other, then applying too little flux may result in easily breakable connections. To solve this problem, apply more flux than usual when joining these objects.

Flux paste is a special type of solder that has an added ingredient to make it flow better. Flux pastes are used when soldering electronic components because they help reduce the oxidation on the metal surfaces, which in turn helps the solder stick to them.