Flux is a substance that helps the solder flow evenly and smoothly, especially when you are working with metals. It protects surfaces from oxidation and corrosion, which can cause problems in electrical soldering. Flux also improves the surface tension of metal joints to make them easier to join together. When you need flux for your next electrical soldering project, it’s important to know what kind of flux you need: rosin-based or acid-based?

Flux is a liquid or pastes that remains on the surfaces of metals during soldering to remove impurities and prevent oxidation. Flux can be either organic, inorganic, or both. Organic fluxes contain substances such as rosin, tall oil, and citrus oils which are natural products from trees and plants. Inorganic fluxes are made from borax or sodium chloride. Both types of flux have been used for centuries by metalworkers worldwide to improve their workflow and make soldering easier without damaging the materials being joined together.

A guide for flux: uses and benefits

Flux is important because it helps with two major tasks: removing impurities from metal surfaces before they react with solder (preventing corrosion) and preventing oxidation during heating (oxidation causes rust).

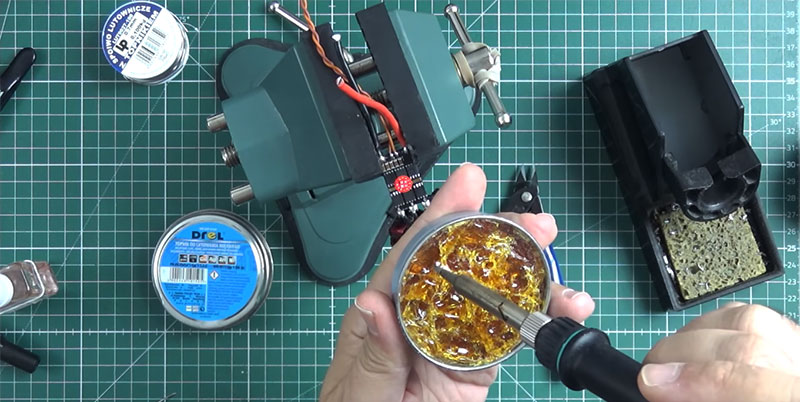

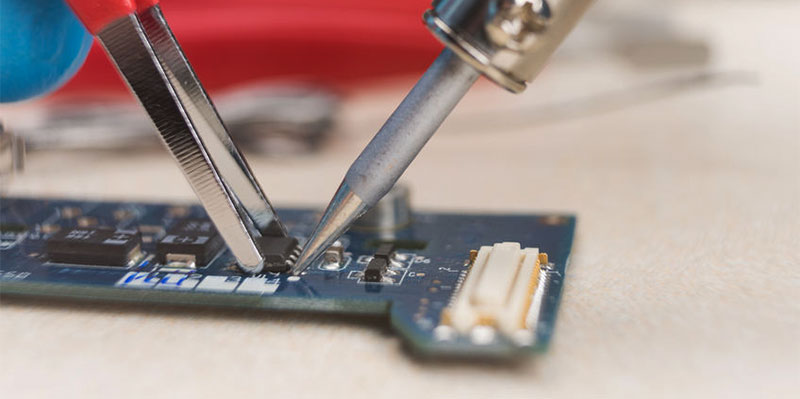

When you’re soldering a circuit, the solder melts and flows to where it is needed. If there is not enough flux on the wires or PCB, the solder will not flow properly. Flux helps remove oxidation from metal surfaces and reduces contact resistance between metal parts which makes soldering easier. The benefits of using flux for electrical soldering are that your process goes much smoother, quicker, and cleaner, with less chance of mistakes being made.

What type of flux do you need for electrical soldering?

Flux is a chemical compound that prepares metal surfaces for welding by removing impurities, melting surface oxides and other unwanted substances, and lowering the melting point of the metal. Fluxes are available in different grades or types, depending on their application. For example, the flux used for electrical soldering is called rosin core solder wire which is a thick paste containing rosin, acid salts, tin dioxide (inorganic), zinc oxide (inorganic), and lead dioxide (inorganic). When this type of flux is applied to two pieces of metal being welded together, it forms a “flux-cored arc” between them as they approach each other. This process melts the oxides from both metals into liquid slag that flows out from under the molten solder.

Flux is an important material that you will need for electrical soldering. It’s a chemical compound that helps protect the metal from oxidation during welding or brazing. Fluxes are typically made up of various chemicals, including acids or alkalis. Depending on how quickly you want them to react with the base metals, they can come in different viscosities.

While some fluxes are available for purchase at your local hardware store, these often have limited uses and may not be appropriate for all projects. For more specialized applications where high-level performance is required, it’s best to go with a professional-grade flux that offers durability and reliability.